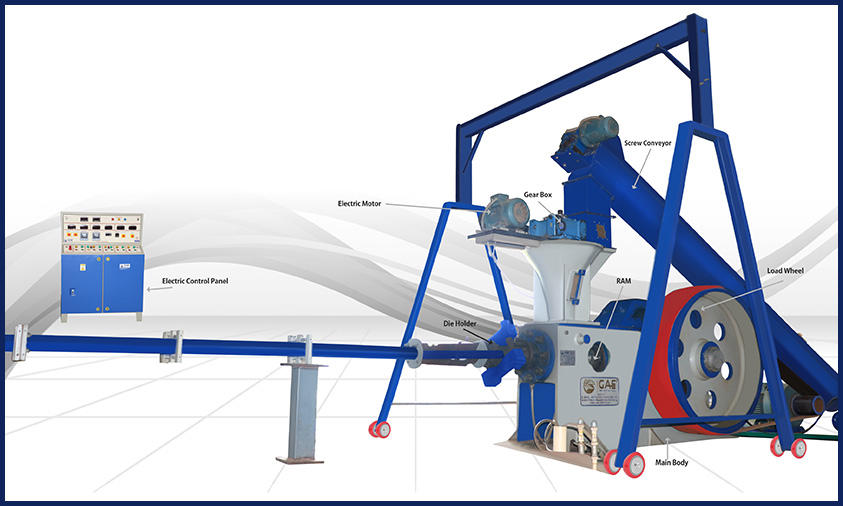

Briquetting Plant JUMBO – 90

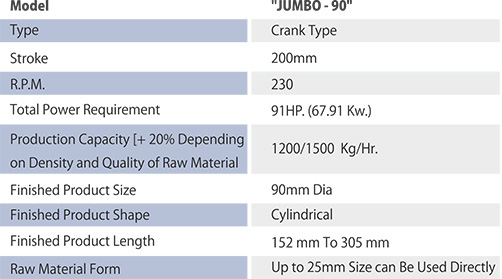

Technical Details For Jumbo - 90

Advantages Of Jumbo - 90

- Saving in Power Consumption

- Increase in Production

- Low Maintenance cost

- Suitable for all type of Raw Materials including Sugarcane Bagasse

- Screw Conveyor

- Easy Handling of Briquettes due to its large size

- deal for Boiler and Fireman.

Processing Cycle Of Jumbo - 90

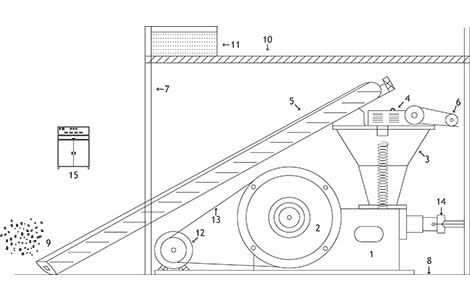

JUMBO – 90 Side Elevation With Backside Conveyer

- Briquetting Press

- Load Wheel

- Kupy

- Reduction Gear

- Screw Conveyor

- Electric Motor

- Bricks Wall of Shade

- Ground Flooring

- Space for Raw Material

- Open Terrace

- Water Tank

- Main Electric Motor

- Flat Belt

- Die Holder

- Briquette Panel

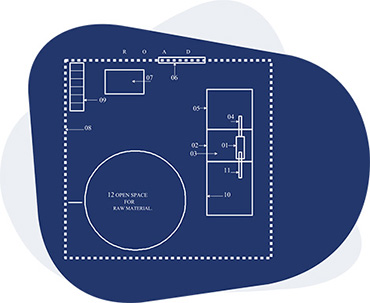

Land Layout of Briquetting Plant

- Briquetting Press (Foundation)

- Shed for Briquetting Plant 30' x 40'

- Reserved space for second Briquetting press

- Cooling Line for Briquetting

- Shed for Briquettes (Galvanized Roof – 40' x 40' Height – 16').

- Entry Gate : (16' long)

- Office building : Two Small Room 10' x 10'

- Shed for Raw Material storage (Galvanized Roof – 60' x 40' Height – 16')

- Compound Wall

- Proposed Labor quarter (3 to 4 small rooms)

- Conveyor for Raw Material Feeding